Function

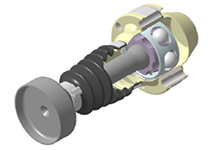

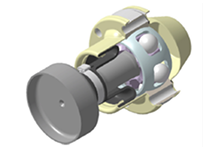

A constant velocity joint for propeller shafts, used in FR and 4WD internal combustion engine (ICE) vehicles to transmit power from the engine to the rear wheels.

Applicable Models

-

SUV

Sportage, Tucson, Kona

-

Other

Tasman

-

Overseas

Jeep Wrangler/Gladiator, Dodge charger/challenger, Honda Passport

-

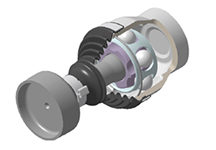

Disc CJ (Cross groove Joint)

- Maximum articulation angle: 4°

- Superior NVH performance

- Lightweight & compact design

-

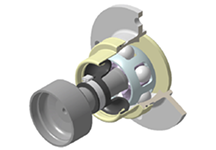

Disc BJ (Birfield Joint)

- Maximum articulation angle: 7°

- Suitable for high-speed rotation and high-angle vehicle models

- Compact design applying a J-shaped boot

-

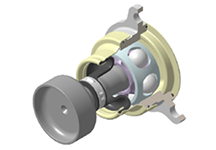

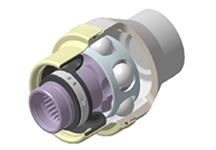

Monoblock CJ (Cross groove Joint)

- Maximum articulation angle: 4°

- Superior NVH performance

- Cost-effective and weight-reduced specification

-

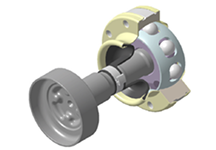

Flange BJ (Birfield Joint)

- 4-hole flange specification

- Suitable for high-speed rotation and high-angle vehicle models

- Lightweight and compact design

-

Flange CJ (Cross groove Joint)

- 3-hole flange specification

- Optimized for vehicle assembly process

- Lightweight design compared to the disc specification

-

Disc HBJ (High efficiency Birfield Joint)

- 8-ball compact design

- High-torque and high-efficiency specification

- Superior durability from low heat generation

-

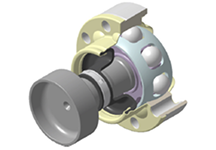

DCJ (Direct Connecting Joint)

- 8-ball monoblock design

- Excellent backlash performance

- Spline structure for direct assembly to the vehicle

-

Disc PSJ (P/Shaft Symmetric offset Joint)

- 8-ball compact design

- Features a symmetrical track structure

- Superior durability from low heat generation